Fresh Storage Methods

Fresh Storage Methods

1. Precooling technology

Therefore, precooling is the beginning of a cold chain and the essential part of subsequent cold distribution and storage processes. Target precooling temperatures of fruits and vegetables in theory are optimal storage temperatures but in practice refer to those shown in the table.

| Product name | Target temperature(℃) | Target humidity(%) |

|---|---|---|

| Cucumber | 7 ±2 | 90~95 |

| Tomato | 7 ±2 | 85~90 |

| Strawberry | 3 ±2 | 90~95 |

- In Japan, precooling technology has become popular thanks to various incentive programs initiated by the Ministry of Agriculture, Forestry, and Fisheries to such an extent that 30~40% of the vegetables shipped to large markets in summer is now precooled and the rate will continue to increase in the future. Precooling has recently been performed not only in summer but also in winter.

- In Japan, precooling facilities employed force air ventilation systems when they were first introduced, utilized vacuum systems in 1973, and began to use pressure release ventilation methods in 1978, which can be deemed to be improvements to forced air ventilation systems, whose use has been on the rise.

- Precooled shipment controls the speed of deterioration in quality after harvesting of fruits and vegetables and ensures maintenance of their freshness from producers to consumers. Advantages that can be expected at each distribution stage include:

● Firstly at the producer stage, the method can reduce products that are subject to returns or discounts and make their long-distance transportation possible and extend their shipment duration so as to rationalize harvesting work.

● Secondly at the retailer stage, the method can reduce waste rates during distribution and sale, thus ensuring safe handling and making planned sales possible.

● Lastly at the consumer stage, the method can elongate purchasable periods and enable customers to buy good quality produce.

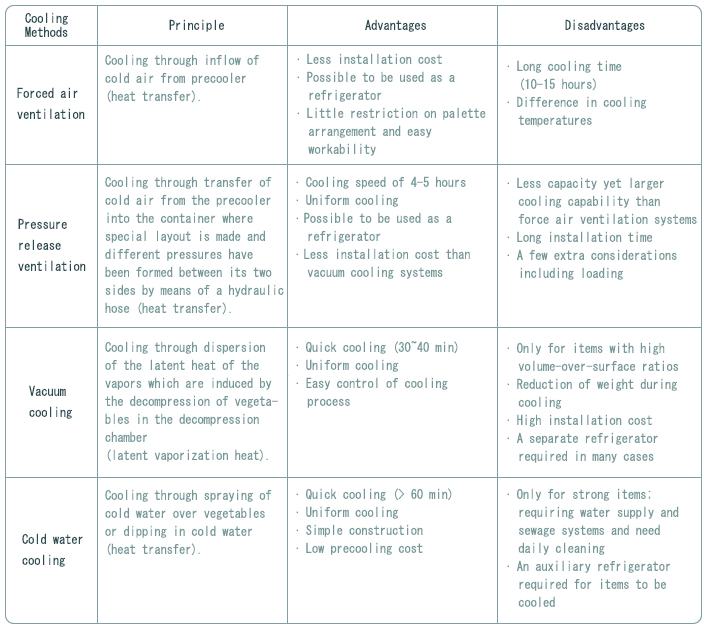

Major precooling processes include force air ventilation, pressure release ventilation, vacuum cooling, and cold-water cooling, the principles and advantages/disadvantages of which are summarized in the table below:

[Types and features of precooling process]

Important points in precooling major vegetables include production of good-quality products, picking of less-than-ripe plants and immediate precooling after harvest, putting of the harvest in baskets and subsequent treatment for blocking of sunlight and heat using silver sheets when there is an interval between harvests, and low-temperature distribution after precooling.

2. Storage environments

Cucumbers are not for long storage; therefore, keeping them in farmhouses or ordinary stores is difficult and costly. Storing cucumbers at room temperature (25oC) in the summertime results in a remarkable reduction in weight by about 10% with the lapse of 4 days. They shrivel and lack luster so that they decrease in their commercial value and will lose its weight by as much as 20% with the lapse of 10 days.

Cucumbers have different low-temperature storage results depending on harvesting time, i.e., the maturation period from their flowering. When buds of (4 days old after flowering) are exposed to temperature of 4~5℃ for 13 days, they are all subjected to impairment due to low temperature; when they are exposed to such low temperature for about 2 weeks within 10 days after their flowering, 20% of them will suffer injury.

Unlike in developed countries where fruits are stored in the industrial scale, CA storage facilities are at their early stages in Korea, covering no more than 20,000m2.

Although fruits can be kept fresh for a long time during distribution when they are stored at low temperatures or in CA storage facilities, fruits are mostly distributed at room temperature in Korea due to the lack of this kind of facilities and distribution methods. As fruits lose their freshness during distribution at room temperature, we need to find ways to overcome such drawbacks as much as possible before CA storage methods can be introduced full-scale. In order to determine limits for room-temperature distribution in an attempt to supply fresh apples to consumers, we began to investigate on such factors quality change, respiration volume, ethylene generation, decay rate depending on room-temperature distribution periods after cold storage, the results of which are summarized as below:

CO2 tended to be generated relatively high during room-temperature distribution; however, apples stored at the CA facility particularly showed a low level of Csub > ₂H₄ that promotes maturation and aging.

For decay occurring during cold distribution, the longer the period, the higher the rate; however, apples stored in the CA facility showed a lower rate than those kept in the low-temperature warehouse.

[2. Limits for room-temperature distribution period after low-temperature or CA storage]

| Though apples are advisably treated to quickly lower their temperature after they are harvested, they are more often than not kept in the shade outdoors- under trees or outside the building- for a long time. There are many cases in which long-time outdoor storage results in high decay rates and deteriorated quality, causing economic damages. Accordingly, we look into changes in the quality of stored fruit according to post-harvest warehousing times and present limits for economic storage duration |

Apples to be sold right after harvesting are recommended to let become fully ripe on trees while those to be stored are to be harvested a little earlier. Furthermore, for those meant to be stored after harvesting, the later the time of storage grows, the quicker the quality gets deteriorated during storage and the higher the decay rate becomes, which means they must be delivered to a warehouse as quickly as possible.

There are, in reality, many cases in which apples are kept at the orchard before they are warehoused because they are harvested over several days and because it is not easy to deal with warehousing on a daily basis on account of the lack of labor in rural regions. As harvested apples display differences during storage in quality and decay rates depending on the times of warehousing, their storage durations need to be varied in proportion.

Apples are living things and continue their physiological activities during storage at low temperature conditions. Storing apples too long causes them to continue their aging process, resulting in weight loss, deteriorated quality, and spoilage and thus leading to economic losses.

Therefore, stored fruit should be checked for determination of storage periods before warehousing, for its quality during storage, and for shipment times before they get aged. The following table shows economic storage period limits calculated with consideration given to in-storage quality deterioration and decay rates subsequent to warehousing in line with the determination of storage periods.

As can be read in the table, the apples that are warehoused in 5 days of harvesting will have a maximum storage period of 150 days; therefore, those warehoused in 10 days of harvesting are recommended not to be kept for longer than 120 days in order to reduce economic losses.

| Warehousing time | Limit of storage period | Remarks |

|---|---|---|

| On the day of harvest | 180 days (end April) | Quality at the time of shipment |

| In 5 days from harvest | 150 days (end March) | Acid content: 0.20%, Decay rate: 5% |

| In 10 days from harvest | 120 days (end February) | Harvest in 175 days after the flowers are in full bloom |

| In 20 days from harvest | 120 days (end February) | Based on 300g |

Fresh strawberries are suitable for short-term storage as they are prone to become spoiled. Freshly harvested strawberries rise up to 30℃ in temperature and go up further higher when they are exposed to sunlight. Their marketability drops by as much as 40% when the temperature continues for about 4 hours. Accordingly, quick action should be taken to precool them under 5℃ of temperature and keep it during transport, storage, and sale as much as possible to minimize losses.

In addition, an attempt to lower the temperature either during low-temperature storage or during low-temperature transport requires a larger cooling capacity, leading to an increase in facility costs and resulting economic losses. However, fully precooled strawberries require only a small cooling capacity or a heat protection as the truck or storeroom only needs to keep the temperature from rising. Accordingly, precooling in the processing of strawberries presents producers a good way to earn good prices from the good quality and reduce qualitative loss and supply good products to consumers.

| To select a precooling approach suitable for the type and shape of produce To avoid missing out on proper precooling time To pay attention to precooling speeds and produce temperatures To take appropriate measures following precooling processes |

This urgency has led us to develop and supply reasonably priced precoolers that individual farmhouses can purchase for their own use.

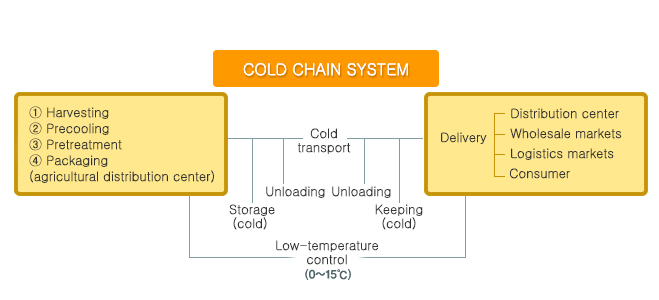

[2. Cold chain system]

Though the academia applies cold-chain systems which are actually imitations of those applied in developed countries, we need to develop products that will meet the needs of our farmhouses.

1. Warehousing

| Placing them outdoors for a long time causes increase in produce temperature; so, quick sorting and packaging are required to make the time shorter. Sorting work should be performed in work rooms or areas laid out for refrigeration. |

| Drying progresses until they are cold-treated in the warehouse as unrefrigerated produce delivered inside the warehouse has higher vapor pressure on their surfaces than those in the room. |

| Warehousing of large quantity at a time must be avoided, since slow refrigeration in its center will cause respiration, deterioration, and fermentation. Accordingly, it is desirable to divide the shipment in small lots and subject them to quick refrigeration. |

| Any decay or mold occurring in a part of agricultural produce before it is delivered into a warehouse will pass its germs or pores to another part and other products in the room and settle themselves inside to become permanent pollutants. As early cultivated fruits are generally harvested in hot and humid seasons, they must be transferred quickly into a storage room so as to reduce respiration. Further, those among medium and late varieties that exhibit a good storing capability should be sorted from those that suffer disease and insect damage or that are bruised, removed of moisture, and warehoused and stored at low-temperature conditions. |

2. Unloading(Stacking of products in warehouses)

| Stacking should be made in a manner the first lot can be easily moved out first. For example, when it comes to a warehouse with a door in the front center, products should be heaped on both sides from near the door along the wall. The center line becomes an aisle that has space wide enough for people to walk through to perform inspection and also to get air ventilated smoothly. |

| When the same produce is divided for short-term and long-term storage, those for long-term storage should be kept in a space where frequent visits can be avoided. |

| They should be placed at a distance of 5~10cm from the wall to let air circulate well. |

| Floor plates or palettes should be placed to provide good ventilation when they are heaped. |

| The same products should be sorted out according to dates; especially those that are not good-looking or discolored should be set aside separately. |

| Products should be stored within 80% of the maximum storage capacity of a warehouse, with a distance of 5~10cm from walls and of not less than 30cm from the ceiling, so as to let cold air circulate well. |

| When coils are installed on the ceiling, products should be stacked in a manner that they do not come close to less than 15cm; when ducts crisscross the ceiling, products should not be stacked above the duct line. It is recommended to make paint marks on the walls to indicate stacking height limits. |

3. Storage

Accordingly, measures should be taken to contain such changes in produce temperature and control its humidity, setting aside unavoidable changes in temperature and humidity inside the warehouse.

| The temperature of stored products changes more slowly and in a narrower range than that of the room. So, small variations in the room cause little change in the temperature inside the produce; however, a slow change occurring over time, if small, will have a significant effect on the temperature when there is good circulation of air around the produce. Accordingly, placing a covering over the produce will produce a good result in controlling temperature changes. |

| When the temperature inside the room goes up, its humidity becomes relatively low, getting stored products to become dry; on the other hand, when the temperature goes down, its humidity becomes relatively high, allowing them to absorb moisture. Packing is recommended to resist such effects. |

|

A normal cooler for a cold storage warehouse must be removed of frost that has formed on its evaporation coils with the lapse of time that results in reduced refrigeration efficiency. For defrosting in a warehouse with an evaporator and a blower installed on the ceiling, turn them off and spray 15℃~20℃ water to remove frost completely before putting the cooling machine into operation again. It is recommended that a temperature control plan should be drawn up with an assumption that defrosting normally requires 1~2 hours every day. If a warehouse uses high-temperature gas or hot wire to remove frost, a time-control device is needed to set the cooling machine into motion after the frost stuck on its evaporation coils is removed completely. As the temperature around the evaporation coils is high after the removal of the frost, it is desired to have a pause of 2~5 minutes, before the cooling machine is set into motion, for the melted water to flow down, preventing the dispersion of the water and lessening a sudden pressure increase at the time of re-operation of the blower. |

|

Circulation of a moderate amount of air is required to keep even the temperature in the cold storage room. Especially, when stacking is under way, a draft larger than that for stored products is required to circulate air to quickly get rid of field heat. In the event precooling has not been performed, the draft fed at the beginning of storage will decide on the speed of lowering temperature; therefore, a large draft is necessary. When the temperature drops to a given level, a draft does not need to be large but only enough to remove respiration heat and keep the temperature even inside the storage room. What is better still is to develop a design to make the air circulate evenly and across every part of the room. |

4. Shipment

Accordingly, measures should be taken to contain such changes in produce temperature and control its humidity, setting aside unavoidable changes in temperature and humidity inside the warehouse.

본문 다시읽기

리뷰컨텐츠는 현재 페이지의 본문내용에 다시 접근할 수 있도록 링크를 제공합니다.